Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Background:

The Toyota Innovation Challenge was a hackathon that challenged us to design a device that automates the placing of stickers (plug plates) over vehicle body holes to prevent water damage and reduce road noise.

Problem:

The current car manufacturing process requires plug plates to be placed manually by workers-- they must identify holes in the vehicle and carefully stick on plug plates.

Our team established the additional requirements:

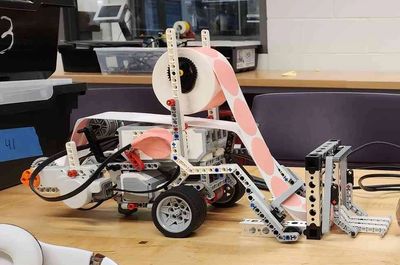

The concept was to utilize a simple motor and create tension on a section of sticker roll, which could create a suitable angle for stickers to be detached from the paper. This is achieved by attaching the end of the sticker roll to a waste paper collector, which rotates and rolls up the waste paper while simultaneously creating tension throughout the roll. Waste paper is slowly gathered into a second roll and can be removed when filled.

The bottom sketches depict the idea of allowing the arm to have a range of motion over a 2D surface. Utilizing a similar mechanism to a claw machine, it moves an arm over a 2D range while the arm itself allows adjustment of angles through bending and rotation.

1. The tension at the bar was too strong and ripped the paper. This was fixed by aligning the unrolling mechanism using software to reduce tension.

2. The device could not be moved within the z-axis. We created a new prototype using a rack and pinion mechanism to raise the bar to a desired height, however, it had a limited range of motion.

Copyright © 2024 hsching.ca

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.